An important research program is the study and application of real-time statistical process control (SPC) in industrial settings. Successful research programs have been applied in the softwood and hardwood lumber industries, cooperage industries, wood composite industries, and water treatment systems. The programs have resulted in development of customized SPC software and reporting, as well as new measurement systems. Annual savings from the studies have ranged from $21K to $750K across all industries.

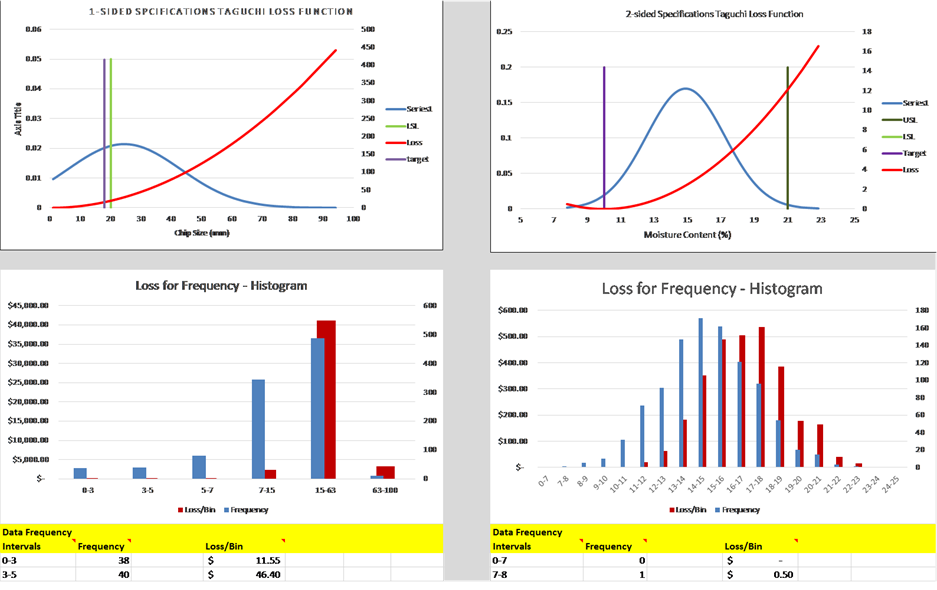

A Simulation Model of the “Bio-depot” Concept in the Context of Components of Variance and the “Taguchi Loss Function”

A simulation of the components of the bio-depot for the knife-ring module, drying module, milling/blending module, and densification module was conducted given the absence of data from the larger research project which was delayed. A Microsoft Excel template with simulation of the variability was developed and may be useful tool for the practitioner.

Considerable attention has been devoted in statistics to the problem of constructing reference bands for the ‘true curve y.’ A method is proposed for developing ‘control bands’ to quantify the non-univariate variation of ‘data signatures’ or ‘process fingerprints’ in the context of the philosophy of the Shewhart control chart, i.e., control limits based on 100(1 – alpha)%, alpha ≈ 0.003. Estimating the control bands based on the Bonferroni inequality with construction of 100(1 -aplha)% pointwise prediction intervals on k observations at each value of X was examined. Control bands were developed for the wavelength signatures from NIR spectroscopy scans of Switchgrass (Panicum virgatum) and core samples of standing loblolly pine (Pinus taeda) trees