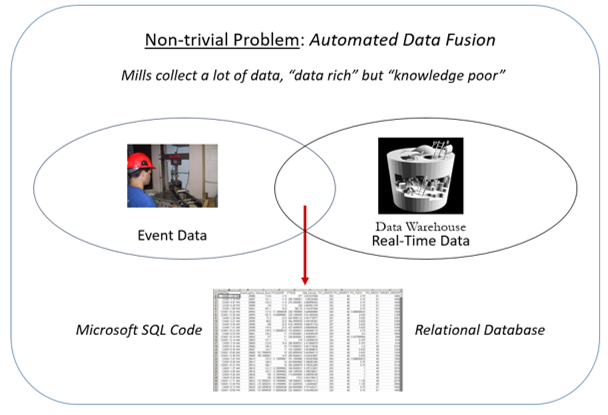

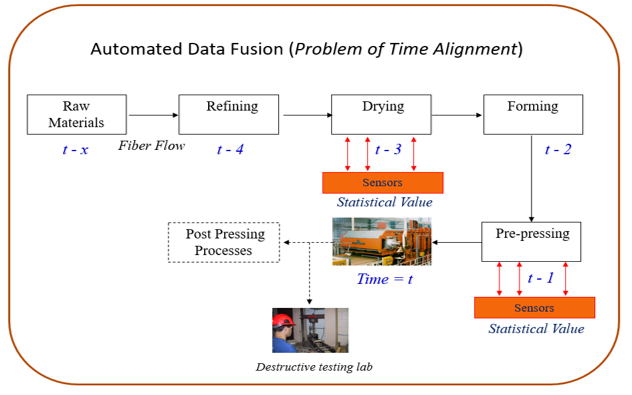

Successful data mining is not attainable without digital data integration and data of high value. The importance of big data, data mining, and AI is emerging quickly in the sustainable biomaterials industries. Liao et al. (2017) suggest a huge gap exists between ‘Industrie 4.0’ laboratory experiments (95.1%) and industrial applications (4.9%). Our research studies collect destructive QC lab results from destructive test samples and align in the proper time order using the ‘date-time’ stamp of each process sensor with the destructive test sample ‘date-time’ stamp. Applied research applications were successfully applied at several sustainable biomaterials manufacturers.

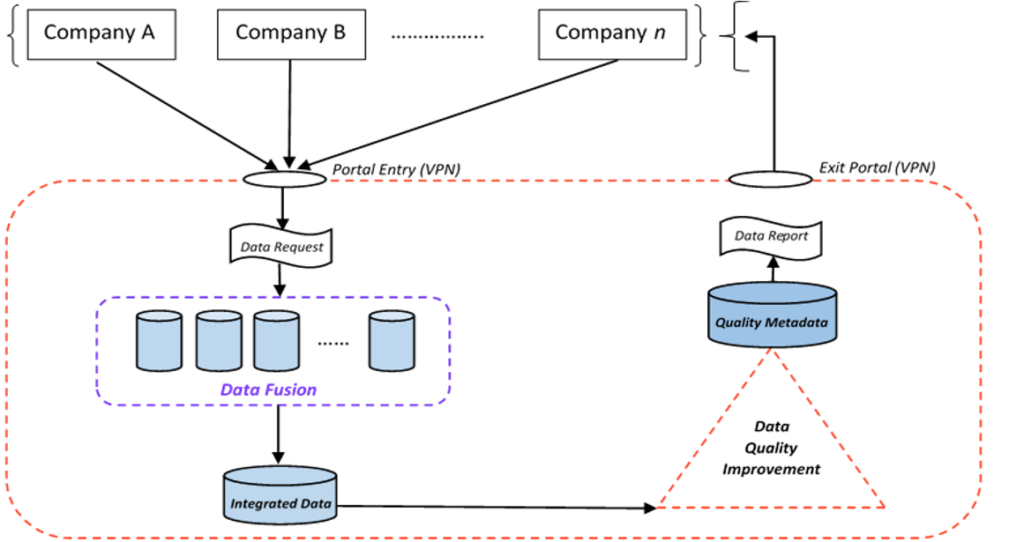

The goal of this research effort is to develop automated data fusion relational database for processing real-time process sensor data aligned in the proper time-order with product quality metrics. This directly supports the principles of Total quality Data Management (TqDM) for ‘Industrie 4.0.’ TqDM and data fusion are both essential elements for successful data mining using Big Data for ‘Smart Manufacturing’ from the Cloud. This creates the necessary foundation for machine learning and deep learning algorithms as part of AI research for prediction. Pragmatic data mining for predictive analytics is the newest initiative for improved business competitiveness.

Publications of Interest:

David Juriga. 2019. Improving manufacturing data quality with data fusion and advanced algorithms for improved total data quality management. The University of Tennessee. https://trace.tennessee.edu/utk_gradthes/5492/

Young, T.M., R.V. León, C.-H. Chen, W. Chen, F.M. Guess, D.J. Edwards. 2015. Robustly estimating lower percentiles when observations are costly. Quality Engineering. 27:361-373. https://doi.org/10.1080/08982112.2014.968667

Young, T.M., N.E. Clapp, Jr., F.M. Guess, C.-H. Chen. 2014. Predicting key reliability response with limited response data. Quality Engineering. 26(2):223-232. https://doi.org/10.1080/08982112.2013.807930